瞩目产品

L-type vacuum bellows heated valves

L-type vacuum bellows heated valves are vacuum valves with an embedded spiral heater following bellows movement, heating the valve body and bellows. Heating from within the bellows eliminates cold spots and enables reduced adhesion of generated material.

Features

The structure enables heating from within the valve, previously impossible with conventional products. Therefore, reaction byproduct adhesion is dramatically reduced, sharply extending maintenance periods and preventing particle reverse expansion.

Bellows internal heater (patented) and external heater temperature can be individually set.

The internal heater can be operated integrally with the valve body, heating both the valve body and the bellows at once whether the valve is open or closed.

Ideal for processes such as metal etching, CVD, and ALD.

Supports flanges including ISO-KF, JIS-VF, ConFlat rotating flanges, ISO-MF, and so on.

A connector can be mounted on the heater and thermocouple cable as well.

Main specifications

- Max heating temperature

-

Controller setting 180°C

- Temperature control method

-

In accordance with temperature controller using K-type thermocouple

- Operating pressure

-

1 × 10-6 to 2 × 105 Pa (abs.) [0.1 MPa]

- Standard material

-

Body: SUS304

Bellows: SUS316L

Actuator A6063

O-ring: FKM

*Materials not indicated are also supported. Inquire for details. - Operating pressure

-

0.4 to 0.7 MPa (G)

- Leak rates

-

Across-the-seat He leak rate: 1 x 10-10 Pa・m3/s or less

Inboard He leak rate: 1 x 10-10 Pa・m3/s or less - Operating voltage

-

AC100V

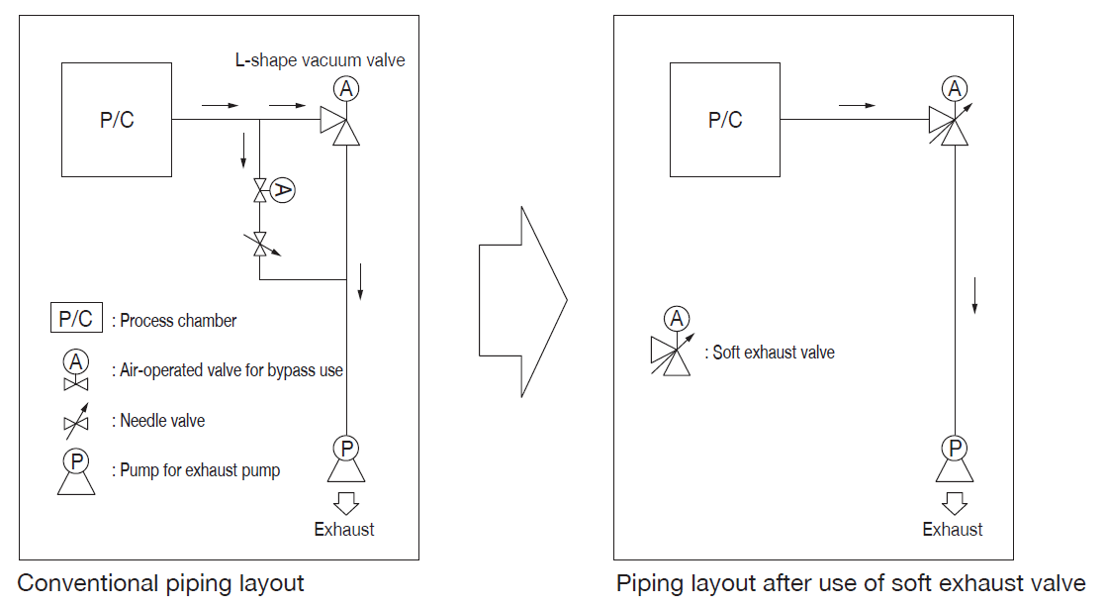

Soft exhaust function (option)

・ The slow vacuum line is integrated with the main valve structure, enabling minimized footprints and reduced costs on exhaust lines.

・ The bypass valve can be heated at the same time as the main valve body heater.

・ Flow rate fixed and variable types are available for the bypass line.