瞩目产品

Dual center rings

Are you struggling with replacement work and facility maintenance costs caused by O-ring thermal hardening, corrosive gases, and plasma deterioration?

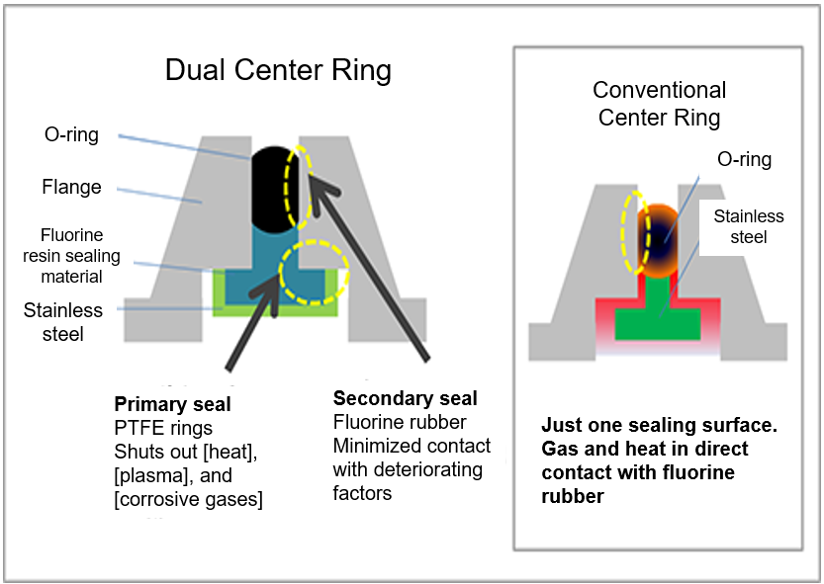

Dual center rings are an innovation making use of the best aspects of fluorine resin and fluorine rubber, improving sealability and safety.

Features

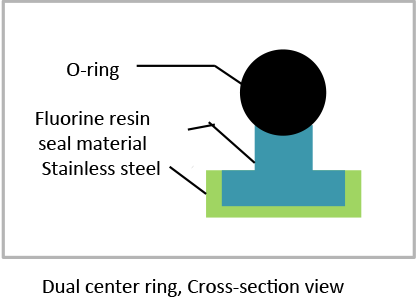

Double seal using fluorine resin (PTFE) and fluorine rubber (FKM)

Primary sealing of gas with fluorine resin reduces O-ring corrosion factors (heat/plasma, contact with corrosive gases) which have conventionally affected center rings.

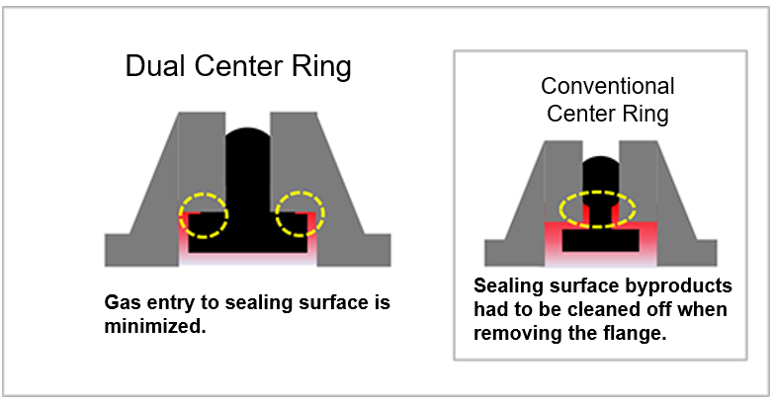

Fluorine resin (PTFE) ring prevents generated material from adhering to the flange sealing surface

With the flange and center ring in close contact, generated material is prevented from adhering to the flange sealing surface, enabling easy maintenance.

Continuous operating temperature up to 260°C

Also usable at high temperatures.

Mounting on various piping sizes is possible without remodeling.

Compatible in use with standard piping joint equipment using center rings.

(NW-KF, NW-LF, ISO-K, ISO-KF, ISO-LF, ISO-MF, etc.)Usable with various sizes of piping.

(Available for NW16 to NW100 (catalog products) and other sizes as well)Usable regardless of the clamp structure.

(Quick Clamp, Chain Clamp, Single Claw Clamp, Double Claw Clamp, Bottle Joint)

With SUS as support material, durability is improved (dual center ring only)

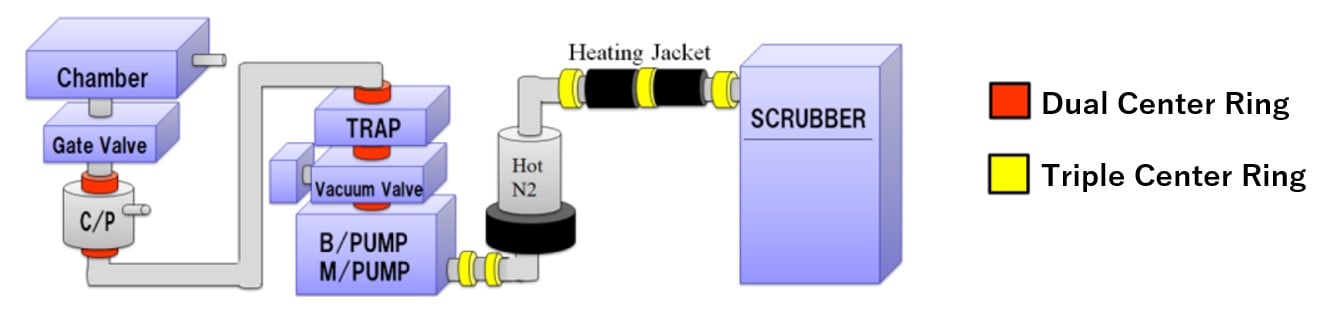

At normal pressure, triple center rings can be used

PTFE + FKM rubber are used. Use at normal pressure is recommended.

Usable range

Usable with center ring as sealing material in clamp piping connecting vacuum exhaust lines in semiconductor/FPD/LED manufacturing equipment, etc.

Specifications

New type

Sizes: 16A, 25A, 40A, 50A, 80A, 100A, 160A, 125A

Materials: SUS, fluorine resin, heat-resistant fluorine rubber

Usable locations: Decompression

Triple type

Sizes: 25A, 40A, 50A

Materials: Fluorine resin, heat-resistant fluorine rubber

Usable locations: Normal pressure, micropressure